Aarau Cantonal Hospital - built on data

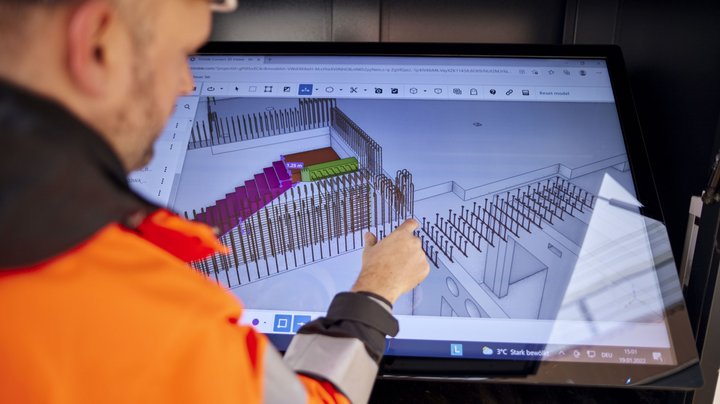

What does BIM2Field actually mean? Patric Sommer: Put simply, the BIM2Field method is the continuation of the digital chain from planning to the construction site. There are no more 2D plans on the construction site; everyone involved communicates using digital building models. These detailed, three-dimensional representations contain geometric information about the shape, size and position of the construction elements as well as semantic information about materials, costs, schedules and other relevant data. This information is called up on site on a tablet or in the digital plan house. Components such as formwork elements or walls are precisely measured using a total station.

It was the first time in Switzerland that the shell of a new hospital building of this size was built using BIM2Field. How was the start? We were a little tense at the beginning, wondering whether everything would work without construction delays on a project of this size. As a backup, we had ordered conventional plans up to the first floor. But we quickly saw that it worked.

What role did Implenia play in BIM2Field in the shell construction? As the total contractor, Implenia's project team had overall responsibility. We were involved in drawing up the concept and coordinating the interfaces with other trades. We ensured the quality management of the BIM2Field models and made sure that consistent data was delivered to the master builder at the right time to avoid construction delays. In this project, the master builder was responsible for work preparation and implementation.

@implenia On the project Kantonsspital Aarau we work wirh innovative technologies and ways of team work. Patric and his team show you how we integrate digital planning in every stage of the project. 🚀 #kantonsspitalaarau#aarau#baustelle#constructionsite#construction#hospital#spital#hochbau#bim#digitalplanning

♬ Original sound - Implenia

"As a backup, we had ordered conventional plans up to the first floor. But we quickly saw that it worked."

Patric Sommer, Senior BIM Manager

What are the advantages of BIM2Field in interior fit-out? The BIM2Field method bridges the gap between planning and execution. This allows the full potential of digitalization to unfold and enables cost-efficient and intelligent work on the construction site. In addition, machine-readable BIM data can be used to prefabricate components such as panels, profiles or building technology components, which is more resource-efficient than cutting to size on the construction site with waste. The prefabricated parts are then delivered to the right place in the building on the construction site as required, assembled according to the modular principle and digitally measured and installed on site. This means that we can also use the BIM2Field method to profitably optimize work preparation and logistics and increase accuracy and efficiency. In addition, the BIM2Field method promotes communication and collaboration within the project team by making digital construction data available on the construction site in real time. The information content of a BIM model enables a better understanding of complex structures and their construction processes.

"Machine-readable data opens up new ways to streamline and automate work processes."

Patric Sommer, Senior BIM Manager

What prompted you to launch a BIM2Field pilot project for the interior fit-out? As a driving force for digital construction in major projects, Implenia has always successfully applied innovative approaches aimed at seamlessly transferring digital preliminary work from BIM planning to execution and operation. This was also the case with the KSA: together with our architecture partner Burckhardt Swiss, we developed a BIM2Field pilot project for the drywall construction. On the one hand, this involved creating installation models that were compared with the actual situation on site using laser scans. Secondly, we worked with a drywall construction partner to define the work processes for the model-based measurement of the walls and substructure.

What were the sticking points when putting this into practice? We were most concerned with the question of how we could take into account dimensional deviations in the already constructed shell and façade elements and comply with the tolerance values for drywall construction, which are in the millimetre range.

What lessons did Implenia learn from this pilot project? In order to be able to react appropriately to millimetre deviations in the shell construction during the interior fit-out, it is crucial to establish a comprehensive and reference system in the building during the shell construction work. We adapt the knowledge gained to subsequent projects.

"We now know how to do this and are ready to use BIM2Field for the interior fit-out on our next project."

Patric Sommer, Senior BIM Manager

How do you take the trades with you on the BIM2Field journey? As always with new technologies, it's also about change management. You have contractors and employees on the construction site who have been working with printed plans for years. This also means that you have to take them along on the journey, involve them and break down inhibitions by familiarizing everyone involved with the new work processes. The plumbing company involved, for example, marked out the suspensions with a laser total station. Their conclusion was: "We don't want to go back. The BIM data is much better in terms of information content, allows us to work more efficiently and expands our expertise.

The new KSA building "Dreiklang" in brief:

- The building concept for the new Aarau Cantonal Hospital focuses on functionality and short distances for staff and patients.

- On a floor area of around 110000 square meters, 472 inpatient beds, 130 day clinic places and 21 operating theatres are planned for the future.

- The new building is divided into three main areas: Outpatient clinics, functional areas and wards. Nevertheless, the areas form a single unit in the overall building.