Innovative solutions for a milestone infrastructure project

“We have great ambitions for this technology, and I hope that we’ll be able to build future projects 110 percent without using paper,” Simeon Hovinbøle tells us. He is Implenia Norway’s BIM-leader on Tangenvika railway bridge. “Our goal is to standardize what kind of information we put into the models, so that we can develop a predictable and quality conscious building process based on these models. I think that we’re on the right track to achieve this goal.”

Simeon works at the Implenia project KS-2 Tangenvika railway bridge, where Implenia will build the longest railway bridge in Norway for Bane NOR. Among his responsibilities as BIM-leader is that the client’s contractual requirements are met, including the implementation of BIM in its entirety. The position entails that you constantly must be updated on the most recent and best digital tools and working methods in the market. The main focus these days is on something called ISY Project.

Project Tangenvika

Bane NOR, the state-owned company responsible for Norway’s national railway infrastructure, assigns Implenia with a contract to build the double-track Tangenvika railway bridge. The railway bridge will be a 1,022 m concrete prestressed bridge and also include a section on land of approximately two kilometers with a wildlife overpass. Extra care is required during construction of the railway bridge since Lake Mjøsa is a source of drinking water with a rich fauna.

Planning and realization of the project are fully digitized using BIM models (Building Information Modeling). The project started in 2022 and is scheduled for completion in 2027.

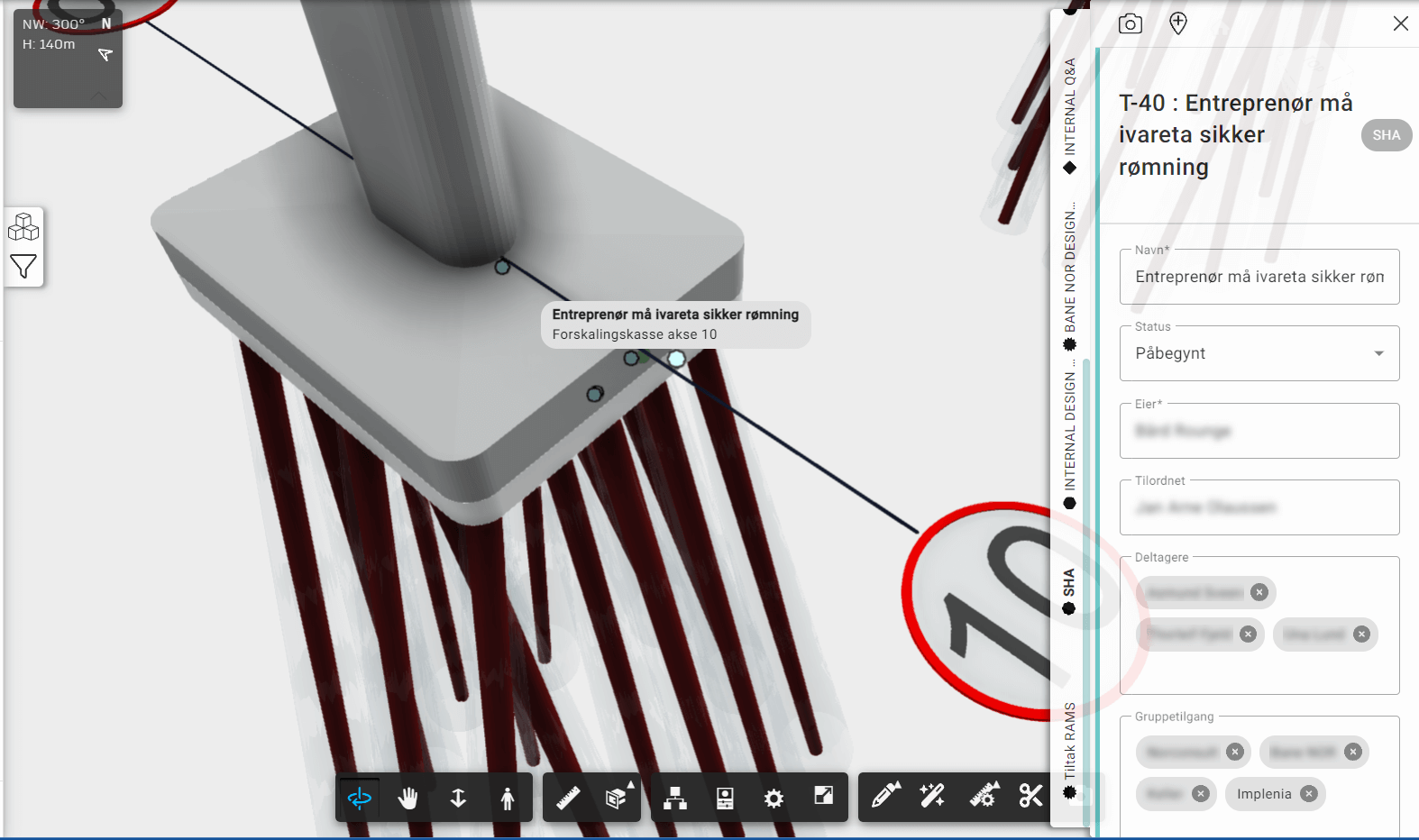

“Quickly summarized, ISY Project is a digital tool that can be explained as an insight tool, meaning that everyone who’s involved in the project are able to look at its 3D-models and all the information that has been added to them,” Simeon explains.

“The strength of ISY Project is that it can connect everything from 3D-models to drone data through what we call case management. Simply put, it binds together everything on the project, and that’s the reason why ISY Project is the key. It makes case management considerably easier, while also making the work we do more transparent by giving everyone access to view what’s happening on the project at any given time,” Simeon adds.

«ISY Project can connect everything from 3D-models to drone data through what we call case management, giving everyone access to view what’s happening on the project at any given time.»

Simeon Hovinbøle, BIM Engineer

Who is ALICE?

It’s the future’s way of building complex infrastructure projects that is being developed at KS-2 Tangenvika. Ahmed Rashid is Implenia Norway’s Head of Planning, and he too works with finding ways to complete construction projects seamlessly with innovative technology. Ahmed has contributed to implement ALICE on Tangenvika railway bridge – but who is ALICE?

“ALICE is a new way to create time schedules on construction projects,” Ahmed says. “The program has its own “AI” algorithm that calculates several different scenarios based on things like equipment, people, cost, and then calculates the best way to execute a project that will save money and time.”

Ahmed was introduced to ALICE a couple of years ago and was asked by the Implenia Group in Switzerland whether Norway would want to be the first country to test ALICE, which Implenia Norway immediately accepted. The reason is that ALICE can an invaluable support tool on construction projects.

“What separates ALICE from more traditional planning tools is that we previously only could get one or two time schedules, while we with can give ALICE all the information we want and create maybe ten different time schedules and scenarios we can modify in real time,” says Ahmed.

«ALICE is a new way to create time schedules on construction projects. Its AI algorithm calculates several different scenarios based on things like equipment, people or cost.»

Ahmed Rashid, Head of Planning

Developing in a sustainable direction

Both Ahmed and Simeon work with technological tools that make planning easier and more practical. The sustainable gains this technology offers makes its implementation particularly attractive.

«The sustainability aspect is absolutely something we’ve kept in mind,” Simeon says. “Things that usually would’ve been caught on the construction site, are now caught through our models before we start building. We have reduced waste considerably while we also save time in that these issues are solved on a computer several months ahead rather than having to have 10 people stand on the construction site and discuss various possible solution that halts production.”

“On Tangenvika we have a more comprehensive understanding of the possibilities and challenges we potentially may face on the project. Even on the more detailed plane, like for instance whether it’s necessary to use double shifts, we have a good understanding of all of these scenarios,” Ahmed adds.

A unique company that is open to test new technology

We’ll soon get to see the practical result from implementing this technology: after the summer vacation Implenia Norway will start to build the bridge on Tangenvika, which will become 1,040 meters long. According to Ahmed and Simeon, whatever the result it will not be for the lack of a will to test new things.

“People ask me whether ALICE only leads to more work on projects, but for ALICE to work you need to have the right people in place. ALICE is only there to facilitate other processes. If people don’t have the right attitude and are willing to try something new, then there is no point in trying to use ALICE – fortunately we have exactly those kind of people in Implenia Norway!” Ahmed concludes.

“The work that Implenia Norway does within BIM is way ahead of others in this business. There is a fantastic mentality in Implenia – if there is some new technology out there that might improve efficiency, existing working methods or processes, then the people here are very open to explore its possibilities. This is one of the major reasons it’s so much fun to work here,” Simeon says.