PWZ Munich: Total contractor model reduces risks for the public sector

In future, they will be rehearsed in the new rehearsal and workshop center (PWZ):

the great tragedies, the rousing comedies and the moving dramas that the Bavarian State Theatre in Munich on its repertoire. The modern L-shaped building creates a professional environment for preparing the productions. Three rehearsal stages, decoration workshops, areas for props and the costume shop as well as a room for musical rehearsals will be created on around 21,100 square meters. The center also offers space for offices, sanitary and social rooms as well as a cafeteria.

Dömges Architekten AG, Regensburg

What will the PWZ house?

Commissioned as a total contractor

Implenia is in charge of the planning and construction. The construction services provider was commissioned with the project by the Bavarian State Ministry of Science and the Arts, represented by the Regensburg State Building Authority. This means that Implenia is responsible for both the design and execution planning, the construction work including special trades such as stage and workshop construction as well as maintenance for four years for all trades (for elevator systems even over 20 years) - and thus far more than in a classic general contractor model.

"We take care of

everything."

Robert

Bschlagngaul

Senior site manager

The all-round carefree package for public clients

"We offer an all-round carefree package and take care of everything - from the major work to the details such as obtaining the permits for the house connections," says senior site manager Robert Bschlagngaul. This has advantages for the client: there is only one point of contact. All planning and executing subcontractors are managed by Implenia. This reduces interfaces and streamlines the amount of coordination and decision-making required.

The total contractor model is becoming more and more popular

As planning and execution are in one hand, cost, quality and schedule reliability can be better guaranteed. The total contractor model therefore significantly reduces the risks for the public sector. It is therefore not surprising that the awarding of contracts with total contractor agreements for large and demanding public buildings is becoming more and more common in Germany. Robert Bschlagngaul is particularly pleased that Implenia has already been able to present the PWZ on several occasions as a showcase project for the total contractor model.

Six Implenia units, eight planning offices and well over 100 trades and suppliers

As a total contractor, Implenia has everything it needs to realize such a complex project. Above all, the construction services provider provides an experienced team that always keeps an overview and has its eye on the big picture. It coordinates the six Implenia units involved (see info box) as well as the eight planning offices involved (stage, workshop, building physics, architecture, structural, electrical, technical building services and outdoor facilities planning) and the more than one hundred subcontractors and suppliers. For example, they provide the dry walls, lay the screed or supply the paint booth for the workshop or the changing table in the sanitary area.

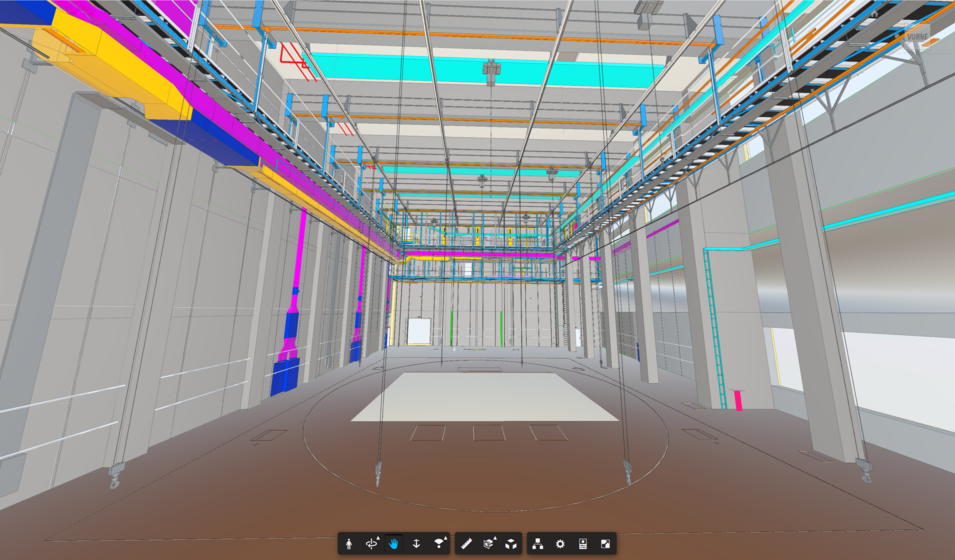

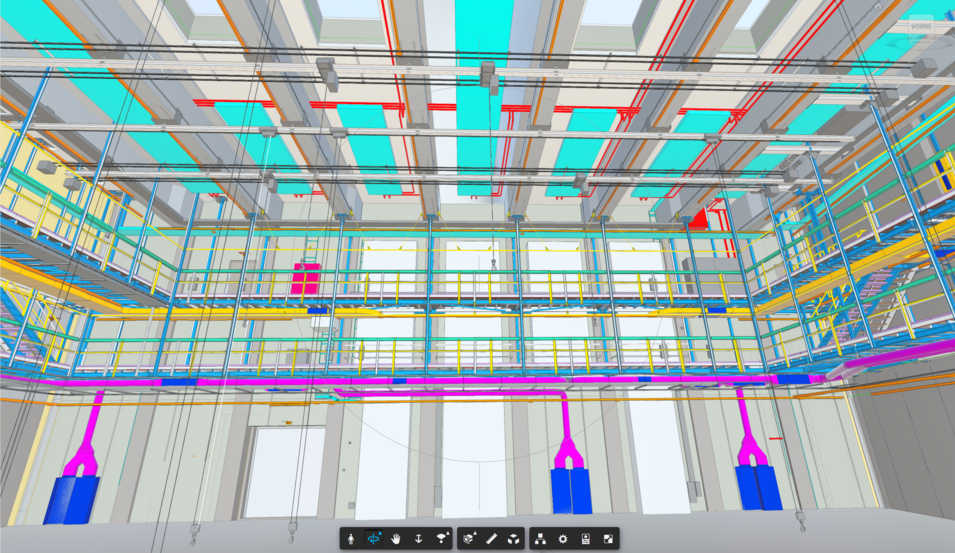

Digital planning ensures successful coordination

The 3D visualizations used on the PWZ construction site provide valuable support throughout the entire process. "They help us to plan interfaces and identify potential collisions - such as the hanger of the steel gallery with the wastewater pipe - in good time and avoid them," explains the senior site manager.

These six Implenia units are involved in the construction of the PWZ

- Building construction - Total contractor and overall coordination, face to the customer

- Special civil engineering - Excavation pit

- Civil engineering - Shell construction

- Facade construction - facade

- BBV Systems - Prestressing technology

- BCL - Building Construction Logistics - Logistics, security, access control

Who does what exactly?

Everything but ordinary

The PWZ is an extraordinary building. It is neither a classic office building nor a conventional workshop or industrial building, but a unique mixture that is completely geared towards the requirements of theater operations. At the heart of the PWZ are the three rehearsal stages, whose dimensions correspond exactly to the stages of the Residenztheater, the Marstall and the Cuvilliéstheater in Munich's city center. This 1:1 reproduction makes it possible to prepare stage sets and productions under realistic conditions.

Overall, the new building has numerous structural features such as

- rooms up to 16 meters high

- column-free halls with steel composite beams and prestressed concrete for load transfer

- an 11-metre-long and 4-metre-wide freight elevator that enables the transport of entire stage sets

- special technical infrastructure such as stage lighting, revolving stages, etc.

- Workshop facilities (metalworking shop, joinery, painting shop with paint booth, assembly hall)

- Vibration supports for damping movements and special impact sound insulation due to high sound insulation requirements

Finding the best routes

However, planning and building such a complex center with many extras also poses special challenges. This is because there is no standard routine as with the construction of an ordinary residential or office building. Instead, it is necessary to find ideal ways of carrying out many tasks that need to be completed for the first time. Robert Bschlagngaul uses the rehearsal stages as an example: "Gallery corridors made of steel are built on the walls, from which instructions are given to the actors and actresses, and the stage spotlights and acoustics are installed - all in a very confined space. Our job is to ensure that the stage construction, building services and acoustics can work in optimum coordination. What comes first? What comes next?"

The perfect interplay

Each step must be perfectly coordinated with the others. And it's very similar in construction and theater: perfect interaction is essential for the result. The construction work is still in full swing. The Implenia team is pulling the strings at the PWZ - with a comprehensive understanding of the project and great commitment. So that it can be 2026: Curtain up for trial operation.

What does a sustainability-certified construction site need?

The PWZ construction site is sustainability-certified. Melanie Sieger, Junior Project Manager at Implenia Building Construction / Munich branch, explains what it takes.

More about the project