Innovation for enhanced safety and ergonomics in tunnels

“After three years on site, this extraordinary infrastructure project has entered a new and important phase,” explains project manager Alexander Heim. “After concentrating on traditional tunnel excavation for the last three years, a second team is now starting to create the final tunnel lining, thus producing the final structure. This means that we now have two teams working in parallel in the tunnel: excavation continues at the front, final lining at the back. The teams share the concrete plant. This makes the whole operation complex and logistically demanding - but it saves about a year's planning.”

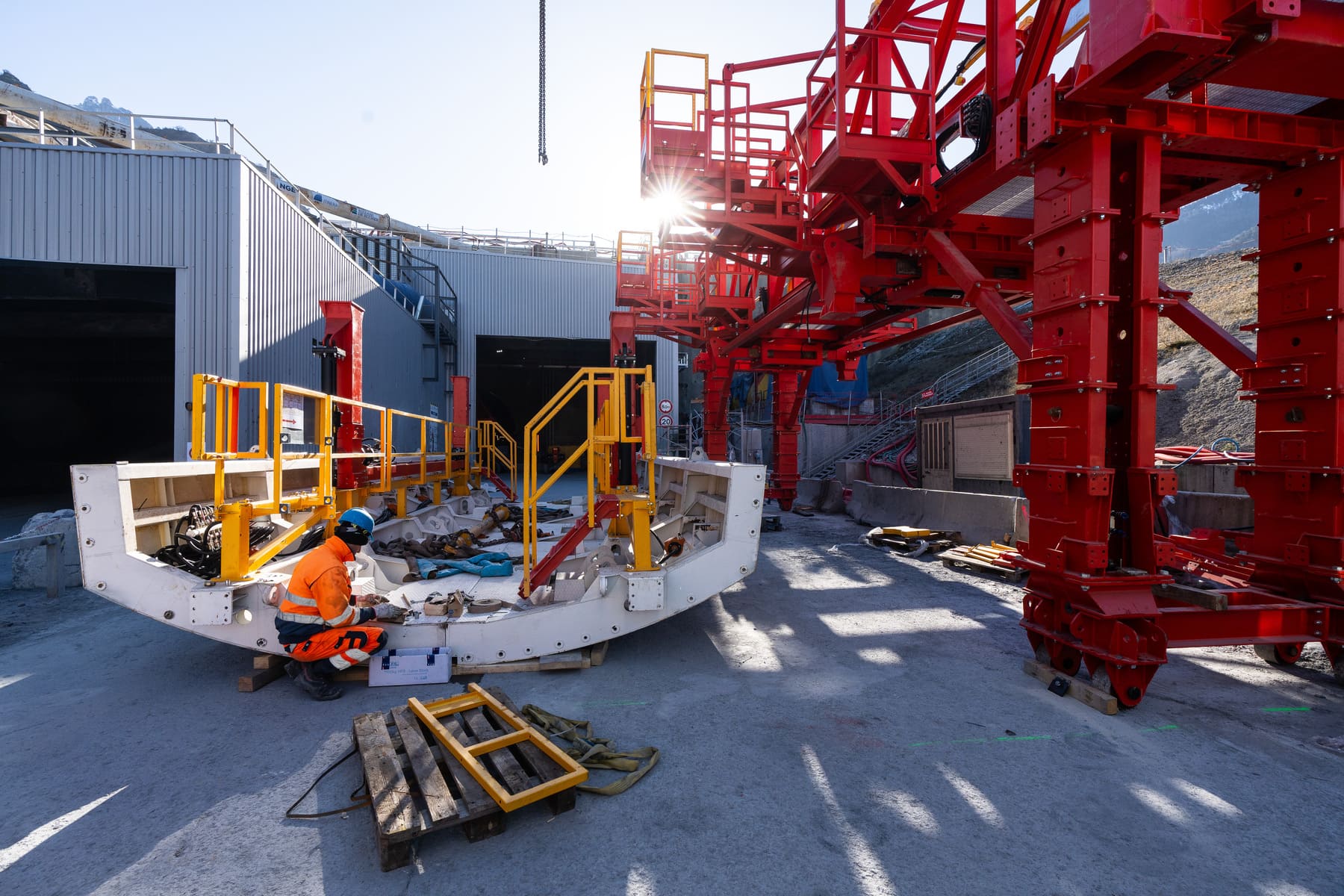

Tunnel floor lining

The second team's first task is to prepare the lower third of the tunnel, the floor formwork. To do this, before the tool comes into action, our workers prepare and rework the ground by projecting mortar. Then, using the tool, they create a waterproofing layer with a minimum of three layers: a geotextile fabric and geogrid, a geomembrane, and a protective black. This is followed by reinforcement, to ensure even distribution of traction forces. Once this work is complete, the final step is to position the formwork to pour the concrete from the back of the machine. This finally forms the solid base of the tunnel floor.

The work steps described require considerable physical effort, as Alexander Heim points out: “For the waterproofing, we produce an extra-strong layer, 3 mm thick and 2 m wide.” The geotextile is delivered in huge rolls weighing around 150 kg each and must be installed around the entire circumference of the tunnel. The geotextile is bolted to the facing with a washer. The geomembrane is welded to the washers, and the strips are welded together. The protective black is then welded onto the geomembrane. Rolls and reinforcement are supplied from the front of the machine, using winches and jib cranes integrated into the machine for ease of handling.

Reduce the risk of accidents

“In this kind of work, where heavy equipment is moved and installed, the risk of accidents is high,” explains Alexander Heim. “Our mission is clear: we are responsible for our employees and must ensure that they return home in good health in the evening. This is what prompted us to develop an innovative, customized tool for tunnel lining.”

To do this, a team including Florent Baulat, Senior Works Engineer, and Karine Puyjarinet, Site Environment Manager and Concrete Referent, began to define what such a machine should do. Seven criteria were defined to make work easier and more efficient: assembly and disassembly, accessibility, access to the machine, workstations, tool handling, maintenance and task automation. “In concrete application, the machine had to transport materials and equipment inside the tunnel and permit the team to carry out their work according to the most ergonomic standards possible,” explains Florent Baulat. “This means that, wherever possible, they should not move loads by hand, and that they should always have all auxiliary aids like lifting and support devices within reach.”

New development with Kern

In partnership with Kern Tunneltechnik in Switzerland and one of their plants in Slovenia, an innovative solution was developed over a 12-month period from existing components. On March 25, 2025, the machine began operating at the tunnel entrance and is now progressing in 10-meter steps towards the tunnel interior. “The smile on the employees' faces when they use the machine's functions are impressive: the tools are adapted to the tasks required,” explains Florent Baulat. “It's always a source of pride to see a working machine transformed from a drawing on a blackboard. Kern's advanced engineering enabled us to design a custom machine. They were able to guide us through the design and assembly of the tool”.

“It's important to invest in an ergonomic process when designing the tool, to adapt the working environment – tools, equipment, traffic, organization, etc. – to the user's needs, with the goal of mechanizing tasks as much as possible,” explains Karine Puyjarinet. “This enables us to check, as far as possible, in advance that the tool is working properly, and then adaptations are made in the factory during acceptance or on site during assembly.”

Project manager Alexander Heim, who is responsible for the 300 staff members at work for the consortium, comments: “Implenia is proud to be involved in the planning and construction of this important part of Europe's future rail network. With this investment in a special lining tool for accident prevention and safety measures, we are contributing to a safer working environment and to the success of the project”.

The TELT project

The Lyon-Turin rail project is a high-speed line currently under construction. The main component of the project is the 57.5 km-long Mont-Cenis base tunnel, which forms a new rail link between Lyon and Turin. The total length of the new line is around 270.8 km, of which 140 km is in France and 46.7 km in Italy. The project is an important element of European rail infrastructure planning and is supported by the EU. It aims to speed up transit rail traffic in the east-west direction between France and Italy and is part of the TEN 6 rail axes between Lyon and Budapest.

Implenia is part of the TELT CO08 worksite, which includes the construction of the Mont-Cenis base tunnel. Implenia has been commissioned to build Lot 3 of the tunnel in 2021, together with partners NGE, Rizzani De Eccher and Itinera Spa. The project involves the construction of two 2,839 m-long tubes to Italy, including 11 safety branches and 140 m of cut-and-cover.

Key figures

| 5.6 km | Tunnel to be excavated |

| 1'018 m | in umbrella vaults |

| 1'078 | arches to be laid |

| 11 | Safety engines |

| 600'000 m3 | Earthworks |

| 2'700 m2 | acoustic hangar |

| over 127'000 m2 | construction site equipment |

| 5 years | Construction time |

| EUR 228 million | Order volume |

| Over 300 people | on site at peak times |