Like a phoenix from the ashes

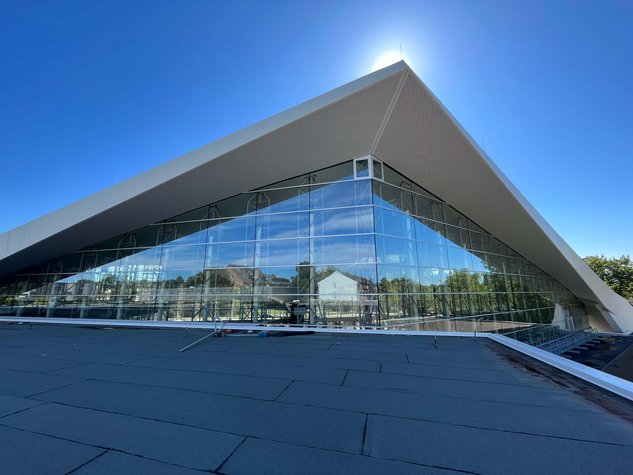

Like a butterfly with outstretched wings, the roof of the Alster swimming pool rests on just three supports and spans the spacious hall. Since 1973, when Hamburg's largest public swimming pool was opened, its architecture has been attracting rave reviews - especially the roof in the shape of a double hyperbolic paraboloid, supposedly one of the most beautiful geometric figures ever. Over the years, countless swimming competitions of all sizes have taken place in the Olympic-sized 50-meter pool. And when the weather was fine, the glistening sunlight filtered through the glass panes of the façade, dazzling spectators and television cameras alike.

As beautiful as it was, decades of continuous operation in chlorinated water (steam) took their toll on the building. At the same time, the requirements of the various users changed over time. For this reason, the operator Bäderland Hamburg GmbH decided not only to preserve the Alster swimming pool, but also to significantly expand its offerings. Since October 2020, the facility has been renovated and expanded for three years with the clear mission of carefully complementing the extraordinary architecture and preserving the defining design elements.

State-of-the-art technology in the original design

The requirement to package state-of-the-art technology in a design true to the original ruled out off-the-peg solutions to a large extent, as project manager Frank Schumacher from Implenia Fassadentechnik explains. "The conservation authorities were heavily involved in this project and also made corresponding demands. Whether it was the aluminum spatial trusses or the door fittings: For every visible element, we had to check whether we could refurbish and reuse the original part. Where this was not possible, we had to find suppliers who could reproduce the original."

LET OUR TEAM SHOW YOU AROUND THE CONSTRUCTION SITE!

"For every visible element, we had to check whether we could reuse the original part."

Frank Schumacher, Project Manager, Implenia Fassadentechnik

The 58 aluminum trusses on which the glass façade is mounted, for example, were dismantled with great care and refurbished by a company in Rostock. In other words, 43 of them were refurbished, while the remaining 15 had to be replaced, as Frank explains: "The new glass façade is heavier than the old one. For structural reasons, we had to have certain aluminum supports rebuilt - custom-made in the original look."

No room for error

The supports are between 4 m and 15.5 m high. Around 80 truck journeys were necessary in the densely built-up area to transport them to the processing plant and back to the construction site. "The logistics were challenging," admits Frank. "For the reinstallation, we had to meticulously plan in which order and at what intervals these large building sections were to be delivered. There was simply no room for error here on the construction site."

The construction was also technically demanding: although the prestressed concrete shell roof measures 102 x 52 m, it is only 80 mm thick - and it swings. The roof must not come to rest on the façade under any circumstances, otherwise there is a risk of shattering. In order to compensate for its amplitude - sometimes it is 30 cm lower than normal, sometimes 30 cm higher - the aluminum supports have a telescopic insert that can be moved vertically and is hinged to the roof. This allows the supports to adapt flexibly to the height of the roof, even in storms or extreme temperatures.

New insulating glass in use

It was clear from the outset that the glass façade itself would not be reused. The old façade was simply glazed, which no longer met today's energy standards. The current façade is an insulating glass unit with an insulating bar in the middle and therefore has completely different physical values than a single pane.

Strict monument protection: the façade had to look like it did in 1973 after the renovation - including ventilation in the form of white plastic pipes, even if these no longer fulfill any function

A curious detail in passing: to prevent the original glass panes from misting up, a ventilation system in the form of white plastic tubes was installed, attached to the supports in front of the window fronts. In the meantime, the ventilation on the inside of the façade has long since been solved differently. "However, we reinstalled the white plastic pipes at the request of the conservation authorities, even though they no longer have any function," smiles Frank. "We just wanted everything to look like it did back then."

Impressions from 1973: The roof of Hamburg | ZEIT ONLINE

The glass elements are attached via horizontal transom layers, which in turn are fixed to lattice supports. The vertical sealing joint, a so-called maintenance joint, must be checked once a year. As part of a maintenance contract, the façade technology team will therefore visit the building once a year for the next four years. Frank Schumacher is delighted: "I've been building façades since 1989 and have seen a lot. Generally speaking, renovation is more complex than new construction - especially in the case of listed buildings. I'm delighted that we were able to hand over this spectacular building on time and have made a contribution to preserving this architectural landmark of the city."

The Alster swimming pool project, Hamburg

Start of construction: November 2020

Completion: November 2023

Construction volume (Implenia services): EUR 5.3 million

Services:

- 2,250 m² demolition and restoration of listed special glass façade

- Disassembly and reassembly as well as new construction/refurbishment of 58 façade lattice girders

- 1,700 m² of new glass and sheet metal façades

Picture gallery

Alster swimming pool Hamburg

Impressive architecture: the glass façade alone is 2,250 m² in size

Implenia Fassadentechnik was responsible for the renovation of the entire façade - including perforated sheet metal panels above the entrance area