Digital building: From vision to profitability

Just imagine: Drones autonomously maintain, inspect and repair building envelopes or construct entire buildings themselves in a swarm. This is still a dream of the future. Many topics are still being researched - for example in the "DroneHub" at Empa's NEST, where next-generation drones and robots are being developed and tested. Yves Serventi, who is responsible for digital construction at Implenia Switzerland's Buildings division, was given an insight during a visit to the site. "Construction with drones already works in miniature - but currently only at the height of a coffee cup and in plastic," he explains. It remains to be seen how long it will take before swarms of drones can construct a real building or maintain facades.

Implenia relies on artificial intelligence here

But the fact is that digital methods and tools are already making construction processes and workflows more efficient. Implenia is playing a pioneering role in BIM and lean construction in many projects such as the KSA. Artificial intelligence (AI) in particular is currently giving digital construction a boost and will probably revolutionize the construction industry in the long term. Implenia is already using AI solutions in various areas:

- AI in the planning phase

In the Tangenvika project in Norway, the ALICE came into play. Implenia is building a more than one thousand meter long railroad bridge over Lake Mjøsa for the client BaneNOR. Alice was used in the planning phase to explore numerous different scenarios for the realization of the project and to examine different combinations of work teams and equipment. This ultimately saves time and money. The project is planned and realized completely digitally with BIM. - AI in the execution

In execution, Implenia uses AI to automatically analyze and identify excavated rock that is carried away by tunnel boring machines on the conveyor belt - optimizing machine control and quality. - AI in contract review

Together with Legartis a Zurich-based service provider specializing in contract review, Implenia is developing an AI module for automated construction contract review, which should significantly speed up the review time of comprehensive contracts in the construction industry. - AI in categorization and documentation

Other AI applications include the automated categorization of tenant inquiries at Wincasa or the automated documentation of construction site images with AI-supported object recognition.

Yves Serventi: What is your job?

"As Head of Virtual Design and Construction (VDC) & BIM at Implenia, I help to optimize processes in building construction in order to generate added value for the company. I also use tools such as 3D models , drones, camera surveillance and AI solutions. I spend 60% of my time working directly on projects, so that I can take on board the real challenges and needs from the field; 40% of my working time is dedicated to the future: I monitor the market, test new technologies, support colleagues in the introduction of innovative tools and review, challenge and define standards."

In building construction, Yves Serventi sees the greatest benefit of AI in the short to medium term in the evaluation of large amounts of data. "There are good tools for supporting processes in office work - such as automatically taking minutes of meetings and defining corresponding tasks. We are also working on automatically checking tender and competition documents in order to compare them with our criteria and identify gaps," he explains. For him, AI is currently increasing efficiency, especially in such repetitive office tasks. It remains exciting to see where progress will be made in digital construction in the future, even outside of AI.

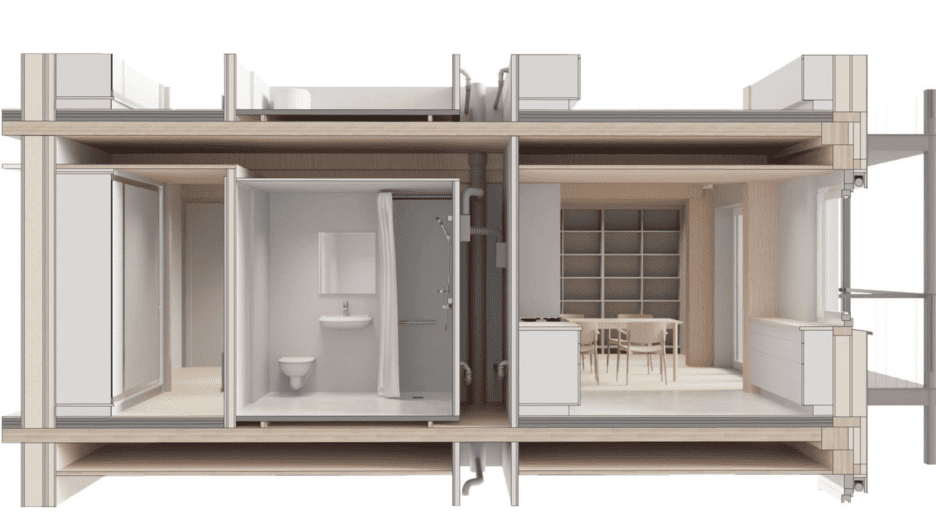

Digitally configurable: modular construction as an opportunity

He sees great potential in modular construction, such as Implenia's "Cabanne" and "Casitta" real estate products for the Dohlenweg project in Zurich Oerlikon. The modular and digitally configurable products bring the advantages of industrial production to bear in the construction phase. This makes it possible to manufacture the building components "off-site" in a controlled, modular, serial production process in order to connect them "on-site" to form the complete property. This shortens both the planning and construction time. Yves Serventi: "The more residential buildings that are built in this way, the better the processes can be controlled, from planning and production to logistics - which in turn has a positive effect on costs and speed." With such innovative real estate products, it is possible to react quickly to market needs, for example by providing apartment types that are particularly in demand - and thus respond efficiently to the housing shortage.

Cabanne: An affordable, high-quality real estate product in modular form

Reality check on technologies: where is the added value?

For Implenia, it is crucial to be aware of new technologies at an early stage because they offer the opportunity to make processes more efficient for customers. The integrated, leading multinational construction and real estate services provider is therefore keeping a close eye on developments in digital construction, testing new technologies at an early stage and implementing innovative solutions - often as a pioneer.

"In doing so, we must always ask ourselves the question: What problem can a digital method solve? What need does the digital tool fulfill? What increase in efficiency can be expected? What added value do the solutions bring and how cost-effective are they?" emphasizes Yves Serventi. In other words, new technologies have to pass the reality check at Implenia. If the cost-benefit ratio is not (yet) given, it may also be the right way to temporarily shelve a promising technology - as was the case with the walking robot used to scan construction progress, for example. "The topic is still on our radar, but we decided to stop actively testing it because the functionalities were not yet fully developed and the costs were too high."

Robots on the construction site: research far advanced, practice not yet ready

In the construction industry, Yves Serventi sees the use of robotics in the future, particularly to relieve heavy or dangerous work, for example when transporting building materials such as bags of cement for bricklaying work. Research and development are already well advanced and models such as the Tesla robot have made great progress. However, they are not yet suitable for construction sites, which are very dynamic. "The robots would have to adapt to constantly changing situations - and they are not yet able to do this."

Conclusion

The future of construction is digital - but not every technology is ready for the market. While construction with drones or the maintenance of buildings by drones and robots are still in their infancy, AI is already revolutionizing planning, construction site processes and office work. Modular construction methods in particular promise additional speed and cost benefits. However, it remains crucial to critically examine every innovation: Digital methods will only create real added value for the construction and real estate industry if their benefits, efficiency and cost-effectiveness are in harmony.